Introduction:

This project is the first intelligent production line of textile machine pulse line in China, and also a representative project of digital and standardized production and process information management in the high-end shuttleless loom industry.

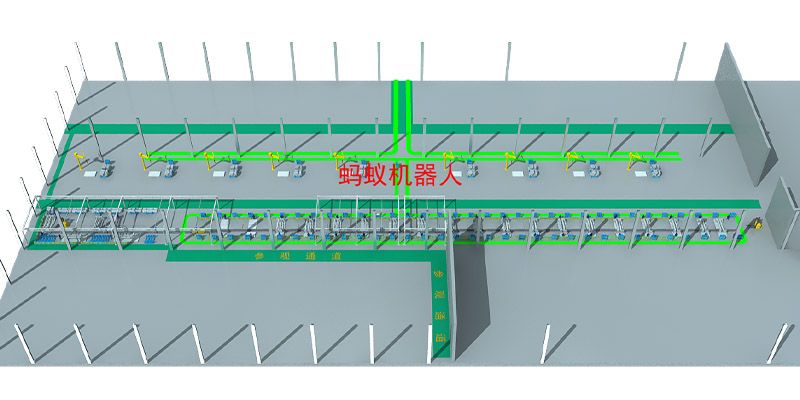

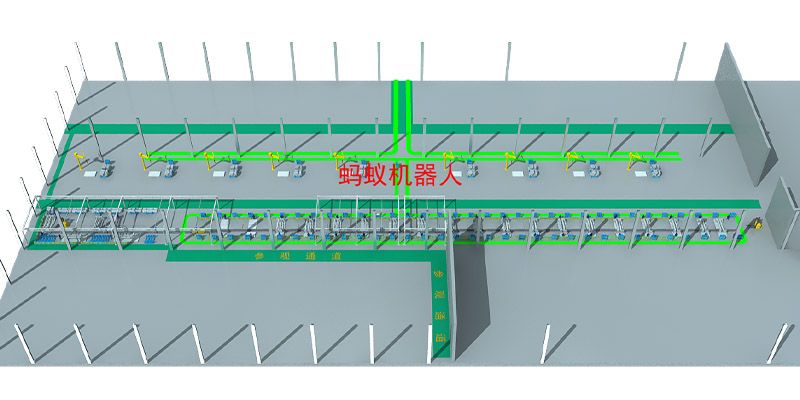

This production line is an intelligent production line integrating AGV automatic material handling equipment, RGV and supporting software scheduling system. Through the automation of platform transfer, line transfer, finished product off-line transfer, finished product warehousing and other processes of loom frame, it shortens the cycle of the supply chain, reduces dull materials, and greatly improves equipment utilization and production capacity!

Reasonable Layout

The project uses 2 QR code-guided AGVs and 2 laser-guided AGVs, 2 laser-guided forklift AGVs, and 16 RGV trolleys. Through reasonable scheduling algorithms, it realizes the scheduling of AGVs with multiple navigation methods to ensure the consumption of materials in the distribution process. Optimal performance and timeliness, while avoiding route conflicts.

Safety Obstacle Avoidance

My AGV supports man-machine integration operation, and can automatically stop and avoid obstacles, advance, retreat and turn in the process of moving, to easily realize the free operation in the narrow channel.

Human-computer Interaction

Real-time monitoring of line process and finished product warehouse dynamic, according to the actual production and the current order batching situation, automatic warning. Bilateral operation planning ensures that employees can operate conveniently, safely, efficiently and orderly, improves material turnover efficiency and shortens supply chain response time.

In today's era, no matter whether "Industry 4.0" in Germany, "industrial Internet" in the United States, or "Made in China 2025" are all emphasizing intelligent manufacturing, using intelligent equipment instead of manpower to realize unmanned production processes. Ant robots cater to the development direction of national intelligence strategy and have been successfully applied to the first domestic textile machine pulsating line intelligent production line, Accelerating the intelligent transformation of automation, intelligence and flexibility in the textile machinery industry.