Industry-leading e-commerce distribution centre in Guangdong

Project Situation & Pain Points:

The first comprehensive warehouse of the top e-commerce logistics group in an industry is faced with problems such as full manual operation, high labour intensity, untimely outbound response, and weak data statistics. The traditional logistics mode is overwhelmed, especially at the e-commerce promotion node, it often faces the pain point of a large number of temporary workers' recruitment and training costs.

Project Plan:

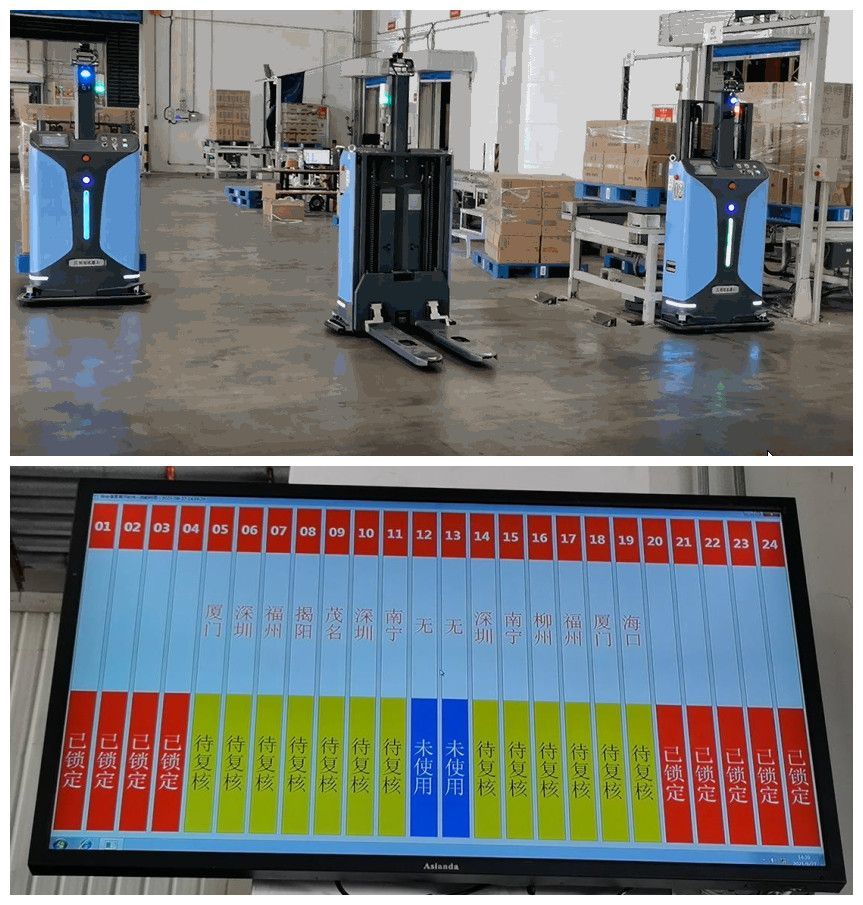

In the warehouse reconstruction area of the project, the ant robot introduces a flexible handling solution to replace manual picking up and transportation from the three-dimensional warehouse platform and move it into the roadway for stacking.

Advantages Of The Scheme:

Cost reduction and efficiency increase: the project introduces three laser slam unmanned forklifts AGV and RCS dispatching system instead of manual picking and handling, which greatly improves the handling efficiency, independent charging, and 24-hour uninterrupted operation, reduces the handling cost, reduces the spacing between ground pallets, maximizes the utilization of storage space and reduces the storage operation cost.

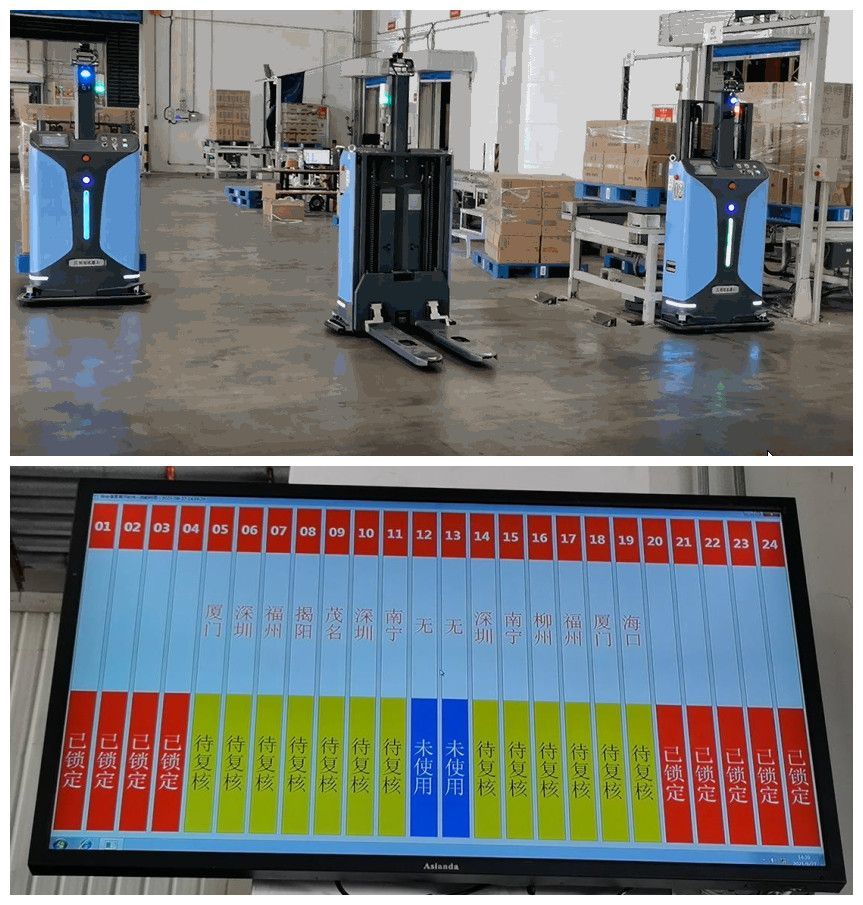

Flexible configuration: given the normal fluctuation of business peaks and troughs, LOGIANT has developed a peak emergency plan for zoning control locking. In the peak period of business, it can lock the designated area and increase manual shipment to flexibly cope with the changes of peaks and troughs, assist workers to complete picking and review, improve handling efficiency efficiently, flexibly and easily cope with the peak flow challenges.

The whole process can be controlled: the ant robot is connected to the WMS system, which can prompt the flow direction, shipment, and disassembly information in real-time on the roadway display board, to realize the openness, transparency, and process of operation information. The ant robot has perfect data analysis ability, which can monitor the operation flow in real-time and continuously improve the whole warehouse process.