The biomedical industry is a strategic emerging industry related to the national economy, people's livelihood and national security, and also an important area for the development of new quality productivity. In recent years, many governments have actively deployed the biomedical industry and encouraged cutting-edge technologies such as artificial intelligence, big data, and robots to drive the intelligent upgrading of the biomedical industry.

The customer is a key enterprise in the biomedical industry chain, facing the needs of personalized demand, order fragmentation, and digital transformation of integrated distribution. To upgrade the traditional logistics model, LOGIANT intelligent warehousing and intelligent logistics solutions have been introduced.

As a manufacturer of pharmaceutical capsules, the working environment is very clean, and the handling vehicle is a stainless steel rack truck with reflective racks and inaccurate positioning.

After the AMR material handling truck is in place, manual operation is carried out, and the position of the material handling truck is different each time, resulting in significant deviation.

The mixed traffic of pedestrians and vehicles on the AMR route affects the efficiency of AMR operation and is prone to safety collisions.

AMR places the material truck on the conveyor, with a narrow safety space.

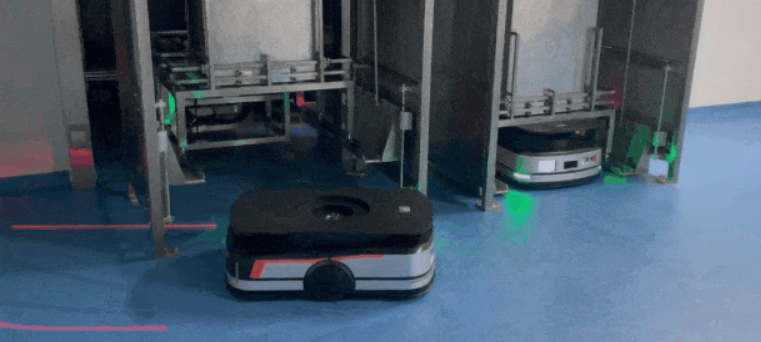

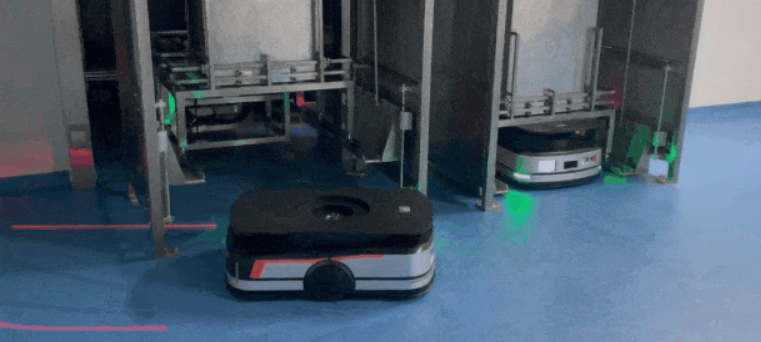

Based on a keen insight into the demands of the biopharmaceutical industry and a profound understanding of production processes, LOGIANT has introduced 20 600 kg hidden AMRs, scheduling systems, and WMS systems to achieve automatic handling of the entire process from scheduling production, pre-allocation of storage locations, process control, equipment management to inbound logistics, achieving information-based, intelligent, and standardized operation of workshop logistics.

LOGIANT lurks and lifts AMR, using a combination of laser navigation, QR code navigation, and texture navigation to provide high positioning accuracy. The material cart is treated with stainless steel sandblasting to reduce surface reflection. Under the digital management mode of warehouse information, achieves a significant improvement from production efficiency to economies of scale.

Adapting to narrow passages and mixed pedestrian flow environments in the workshop, it can safely and frequently transport large and overweight materials between various processes.

According to the requirements of the scenario, achieve efficient, sterile, and timely delivery of required materials.

High picking accuracy, timely delivery, significantly reducing manual labour intensity, and overall improving logistics efficiency.

In the future, LOGIANT will continue to deeply cultivate technological innovation and product research and development, maintain close communication and contact with industry partners, continuously optimize and upgrade product services, and create a new benchmark for intelligent logistics for more upstream and downstream enterprises in the biopharmaceutical industry.