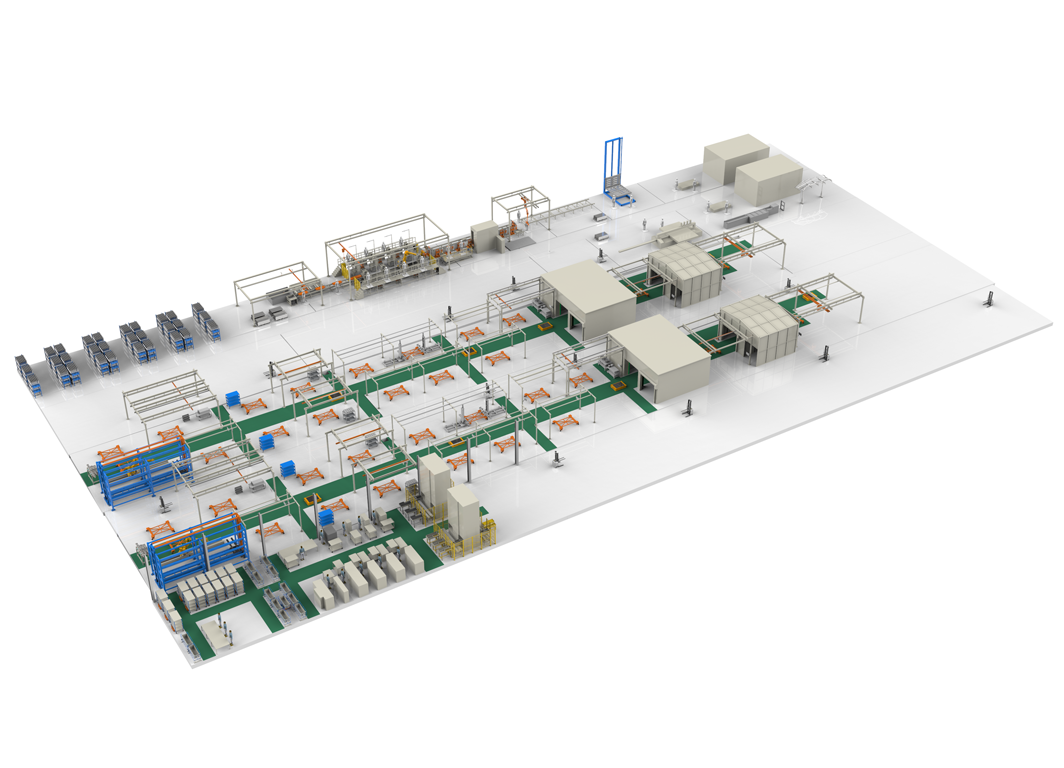

In Longertek technology air conditioning intelligent production line

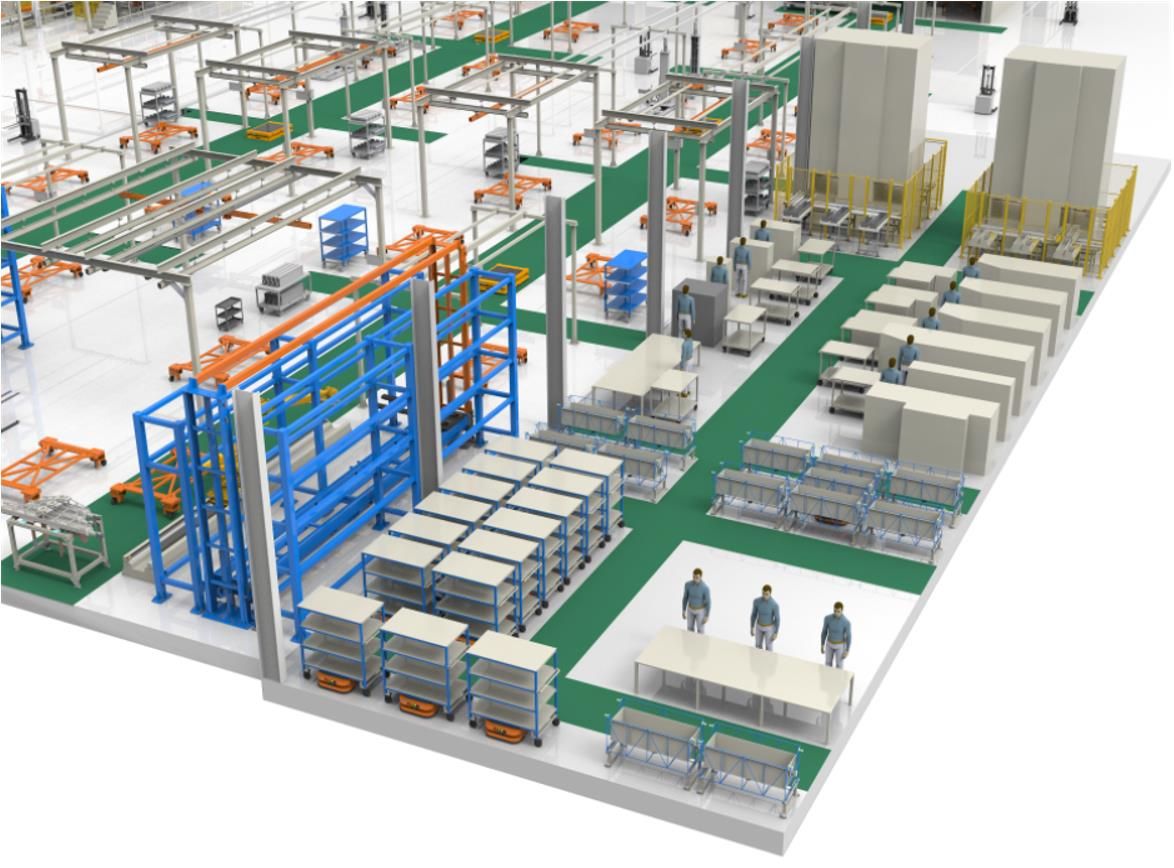

Ant robots has been put into three models

A total of 16 laser slam navigation AMRS

Among them, 8 sets of in-line assembly AMR, 4 sets of on-line distribution AMR and 4 sets of forklift distribution AMR

The communication between modular assembly units of air conditioner is realized

Flexible scheduling and handling

In the actual calculation of air conditioning capacity

A. The production capacity of type B and C increased by more than 50%

Help langjin technology to build an industry-leading

Digital chemical plant demonstration project

Shandong Longertek Technology Co., Ltd., established in 2000, is committed to the R & D and promotion of rail transit vehicle air conditioning and variable frequency energy-saving air conditioning technology. It is the only high-tech joint-stock enterprise in the industry with international advanced variable frequency energy-saving core technology, refrigeration system control technology and big data intelligent maintenance technology. As a leading enterprise in China's rail transit variable frequency air conditioning industry, The market share is rising year by year.

Longertek technology's products include high-speed rail air conditioners, pure electric bus air conditioners, industrial large-scale air conditioners, etc. they have many types, heavy weight, strict quality requirements and large demand fluctuations. In addition, the safety and stability of intelligent equipment need to be guaranteed in the environment of mixed pedestrian and vehicle transportation and material handover, which puts forward higher requirements for the digital upgrading of langjin technology's intelligent factory.

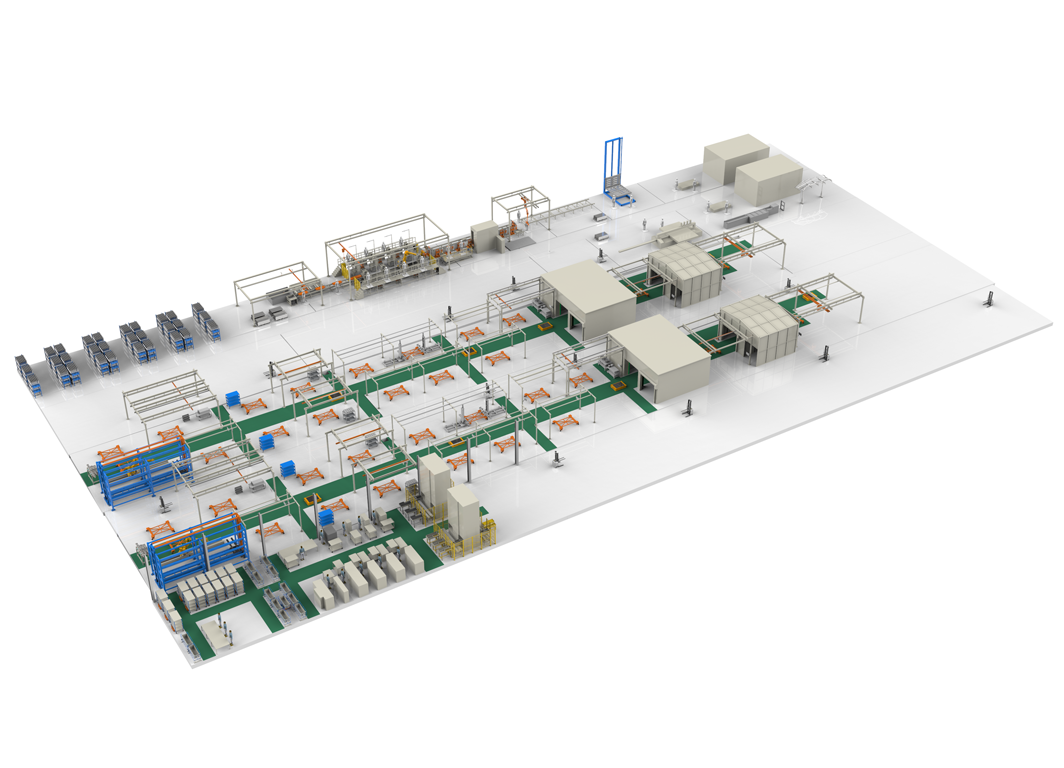

Phase I rail air conditioning assembly line of digital chemical plant construction

Through the modular grouping of air conditioning assembly and production, combined with the characteristics of large size of air conditioning products, small channel width and mixed operation of manual and AMR, LOGIANT adopts three kinds of 16 AMRS to realize in-line assembly and online distribution.

| | |

| A15Lload1500kg,

Laser slam navigation

| |

Latent lifting AMR | L06load1500kg,

Laser slam navigation | |

| FDD14load1400kglift1600mm,Laser slam navigation | |

The laser slam omnidirectional AMR has been innovatively developed in the assembly line. The AMR can move forward, backwards, traverse and rotate in place. The diagonal dual laser is used to realize 360 safety protection and safe man-machine hybrid operation.

With its flexible deployment and high flexibility, RCS not only realizes multi-vehicle scheduling but also greatly improves the production efficiency and information management level.

The ant RCS large-scale scheduling system is designed and arranged reasonably, maximizes the use of space, multi-scene and multi-type AMR division of labour and cooperation, efficient and smooth operation and orderly operation.

Ant AMR, combined with the WMS / RCS / WCS system, can connect manipulators, automatic doors, hoists and other equipment to realize the flexibility and intelligence of logistics in the whole process of material warehousing, outbound, production handling and finished product warehousing.

Automatic grasping with manipulator

Automatic call door switch

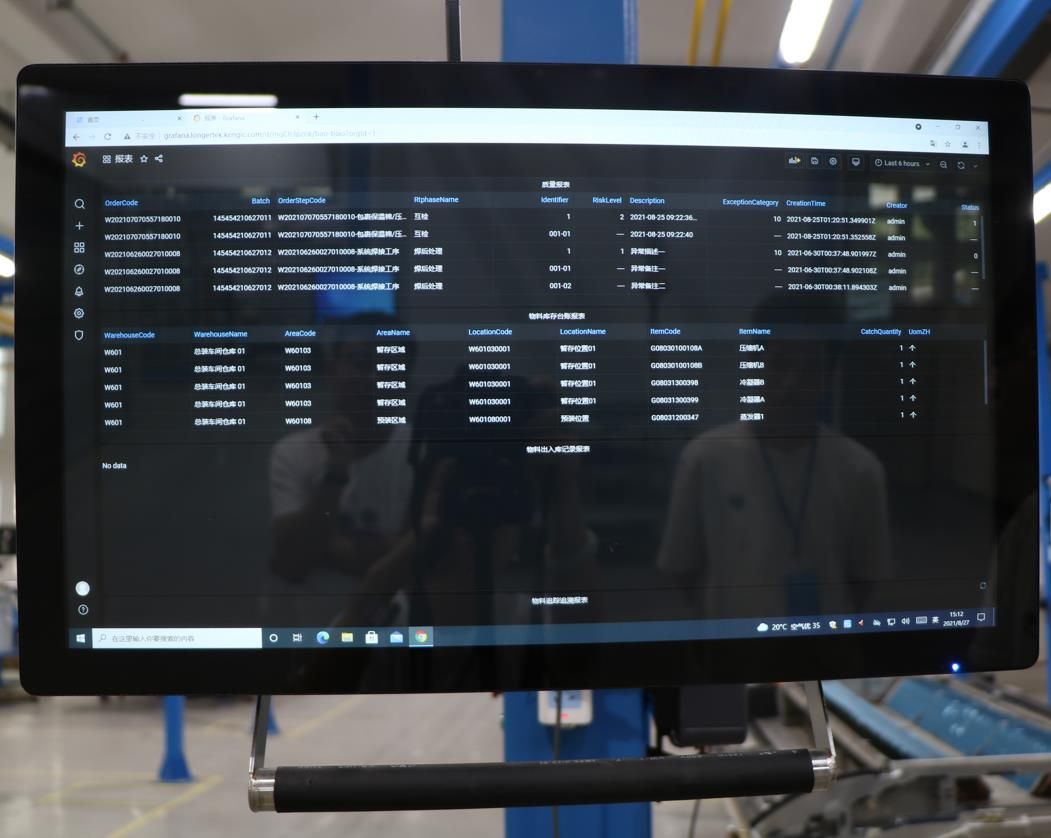

Ant RCS interfaces with MES, SCADA and WMS information systems, provides rich data interfaces, supports a variety of data acquisition, and helps to improve the level of digital information management.

Ant robot has been recognized by customers in the phase I project of a digital chemical plant. The two sides will jointly promote the implementation of AMR and solutions based on ant robots in the phase II project. Ant AMR will continue to empower, and help enterprises to make in-depth changes in intelligence and digitization, and improve the stability and competitiveness of the industrial chain and supply chain.

Ant robots focus on the independent R & D and design of mobile robot systems. Starting from the user scene, LOGIANT is committed to providing customers with internationally competitive intelligent logistics solutions. The main members of the company started the R & D and application of mobile robot ontology and system in 2016 and obtained several independent intellectual property rights of AI and logistics technology. Relying on Kejie intelligence's extensive application and technology accumulation in warehousing and logistics, express sorting and intelligent manufacturing industries, and through continuous R & D investment and project implementation, it has rich experience in unmanned projects in many industries such as engineering machinery, medicine, 3C, special supporting, automobile logistics and intelligent manufacturing.