Thailand Cold Chain Warehouse Smart Project

A well-known cold storage enterprise in Thailand has introduced an efficient, flexible, and stable intelligent handling solution using Ant Robots. With 13 Ant Robots as the connecting point, it connects on-site logistics, achieves full process automation, and leads the multi-dimensional upgrade of modern intelligent cold chain logistics.

With the globalization of smart logistics, Ant Robotics continues to expand its business overseas. Recently, Ant Robot's intelligent logistics solution has once again landed in Thailand. Through demand research, solution communication, and product selection, Ant Robot provides the cold storage enterprise with a flexible solution that combines software and hardware, including 13 latent lifting AMRs, Ant RCS intelligent scheduling systems, and charging piles. This achieves full process automation, improves transportation efficiency and accuracy, reduces labour operating costs, and enhances efficiency.

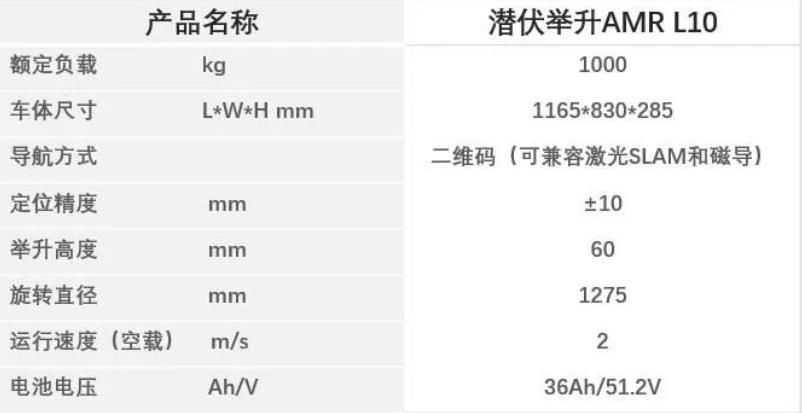

Ant latent lifting AMR product parameters

Dynamic real-time display of scheduling switching between Chinese and English

The RCS scheduling system, independently developed by Ant, adopts a switchable Chinese and English interface, which facilitates customers' better understanding of system information. Visualization of the monitoring interface, displaying the operation of the work area with real images, comprehensively managing the operation status and path planning of AMR 24 hours a day, optimizing logistics management capabilities, and achieving full field logistics automation, efficiency, and informatization.

Switching between Chinese and English

Autonomous and third-party facility interaction

The Ant RCS intelligent scheduling system seamlessly integrates with the customer's upper-level business system, achieving high-precision connection between AMR and various automation equipment, including interaction with automatic doors, automatic docking with elevators for cross-floor tasks, completing unified resource scheduling, and achieving digital management of warehouse information.

Flexibly respond to complex scenarios of human-machine mixed fields

The project site covers multiple material collection points with a limited channel width. Ant AMR is equipped with LiDAR, which can sense the working environment information in real-time, and flexibly and efficiently respond to complex scenes. Laser and collision bar detection as well as emergency stop buttons around are configured, and multiple safety obstacle avoidance designs are implemented to ensure the safety of people, vehicles, and goods.

High efficiency and high inventory rate

High-density narrow tunnels achieve high efficiency and high storage capacity

The cold chain smart warehouse built by Ant Robotics in Thailand features compact workstations, and high-density narrow alleys, effectively reducing channel area, and greatly improving operational efficiency and storage capacity. With multi-path optimal planning and multi task load balancing, it further achieves cost reduction and efficiency increase in warehouse operations.

Ant robots adopt flexible solutions for logistics automation upgrades, deploying 13 AMRs in different regions. Empowered by AI algorithms, they optimize the path mileage of ants, cooperate with intelligent queuing strategies, avoid traffic congestion in narrow channels, drive efficient cluster scheduling of cold chain logistics, collaborate efficiently with various intelligent devices, and achieve fully automatic inbound and outbound operations. Respond to the needs of customers in the cold storage industry with more precise, efficient, and secure solutions, empowering cold storage enterprises to upgrade intelligently.

Ant robots have high flexibility in handling AMR and advanced algorithm strategies, a strong research and development team, and rich project implementation experience, covering scenarios such as handling, picking, in and out of storage. They connect the entire process of warehousing, loading and unloading, sorting, handling, assembly, and outbound, and improve overall logistics efficiency through personalized customized solutions.