Recently, an automated warehousing project jointly built by a well-known household appliance manufacturer in Thailand and ant robot was officially put into operation. The two sides opened a win-win and shared cooperation mode, realized the business needs of automated logistics transportation, loading and unloading, improved the overall operation efficiency of the warehouse, and helped the enterprise upgrade its digital intelligent logistics.

Project Overview

To change the traditional logistics operation mode, improve the overall logistics efficiency and reduce the logistics operation cost, a well-known household appliance manufacturer in Thailand has introduced a complete set of intelligent warehousing solutions such as ant robot latent lifting AMR, RCS scheduling system and charging pile. According to the project business process characteristics, site layout and various technical indicators and requirements of customers, combined with the mature product characteristics of ant robot, modular functional components and standardized structural design are adopted to realize the logistics automation between all processes of the whole plant under the management and scheduling of RCS, and greatly improve the operation efficiency and information management level.

Solution

Ant lurking lift AMR L06

The two-dimensional code navigation with mature technology is equipped with visual recognition, which is compatible with laser slam and magnetic navigation. It is equipped with a new generation of main control chip and has more sensitive navigation ability.

Industrial appearance design, large-scale application verification, no need to transform the environment, fast deployment, and adapt to complex application scenarios.

Standardized and modular design is adopted, and components with the same structure have good interchangeability.

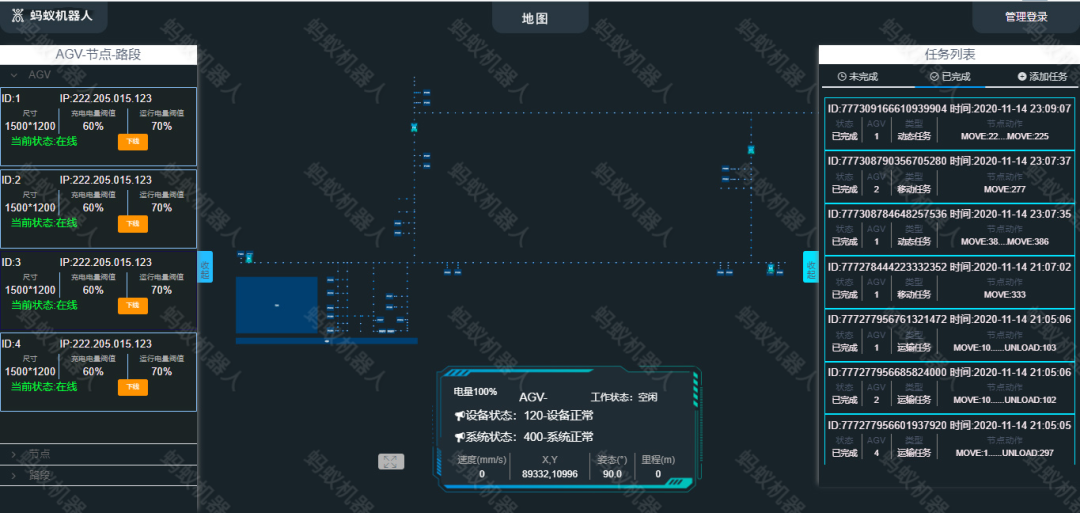

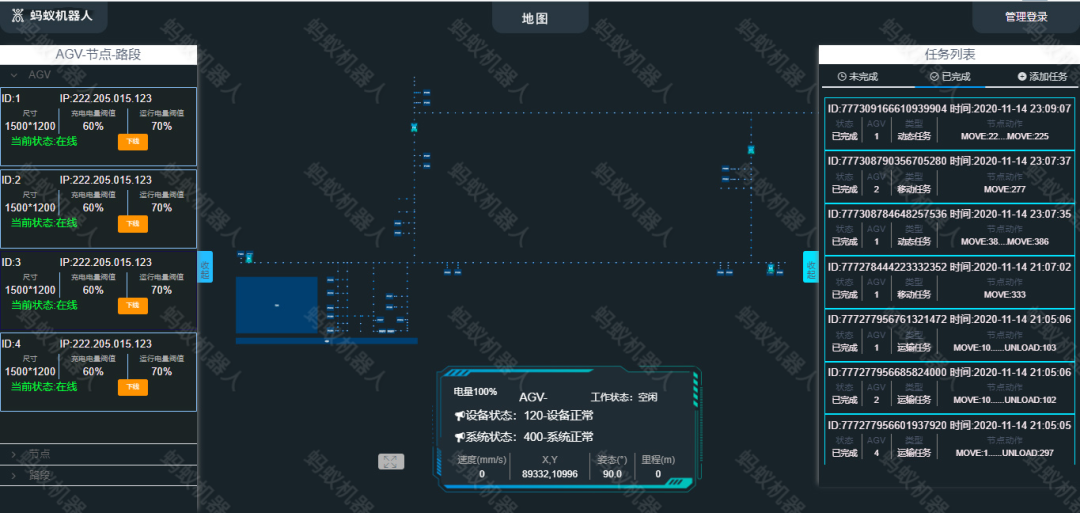

Ant RCS dispatch system

Ant RCS self-developed scheduling software is connected with the warehouse management system WMS and the mobile robot at the executive level to realize equipment interconnection, data exchange, and information visualization, comprehensively control the vehicle operation status, and promote the intelligent process of warehouse logistics through intelligent traffic management scheduling and unified planning of complex routes.

Charging point

The battery management system independently developed is adopted to monitor the battery changes in real-time. In case of any abnormality, the power supply shall be cut off immediately; It has automatic charging, manual charging and high-power battery charging modes to meet the charging needs under different circumstances. At the same time, the ant robot can dock with the charging pile independently when it is low power and idle.

Program highlights

Collaborative interaction quick response

The RCS dispatching system developed by the LOGIANT robot can carry out cluster control, traffic control and path optimization for robots, ensure the independent, orderly and collaborative operation of multiple vehicles, open up the logistics in the plant and realize the automation of the whole process.

Whole process traceability flexible management

The RCS dispatching system is connected with the user Warehouse Management System WMS to realize the linkage of material information, traceability of the whole process, flexible management, and meet the requirements of intelligent handling and lean management.

Cost reduction, efficiency increase and quick return

Ant robot automated logistics solution reduces the labour cost and storage space use cost, improves the overall operation and maintenance efficiency of the project, and truly realizes rapid return.

Ant robot has rich project experience and professional solutions to ensure the successful delivery of the Thai project. After the project is launched, the existing work processes are seamlessly connected with LOGIANT robots to quickly respond to customer needs. Through the system robot coordination and intelligent scheduling, the flexibility and handling efficiency of the project are improved. In the future, LOGIANT robots will continue to enable more enterprises to realize intelligent upgrading with its global operation and service capabilities.