Recently, Ant Robotics and a 3C industry giant, a certain electronics company, collaborated again to successfully deliver a full process flexible AGV handling project. This is the second cooperation since the first cooperation between the two sides in 2020 to create a benchmark for the transformation of 3C industry's smart logistics. The client highly affirmed Ant Robotics' product technology and solution leadership and chose to engage in deep cooperation with Ant Robotics to explore innovative solutions, injecting new momentum into the future of 3C.

This client is a global company with over 50 years of history and annual sales of $14 billion. They have factories in over 20 countries and mainly produce various connectors, internal connection devices, and related raw materials. Their products are sold to the international market.

The customer is in one of the world's largest production factories, using manual push of different material carts to and from the online warehouse, packaging area, and outbound area. The factory spans three floors, with complex operating scenarios covering the entire process of warehousing, storage, handling, and outbound. Due to the fine and diverse electronic materials, as well as frequent production line changes, the manual workload is high and efficiency is low. We hope to leverage automation and digital management capabilities and accelerate the digital upgrading of factories.

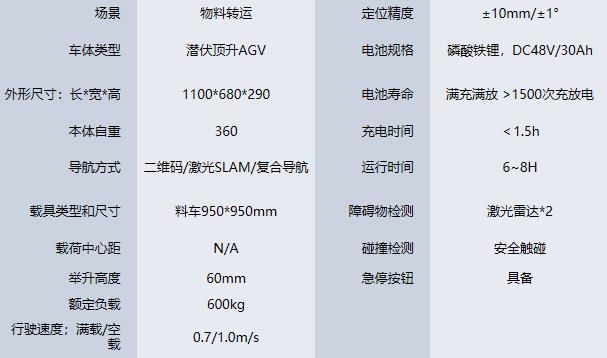

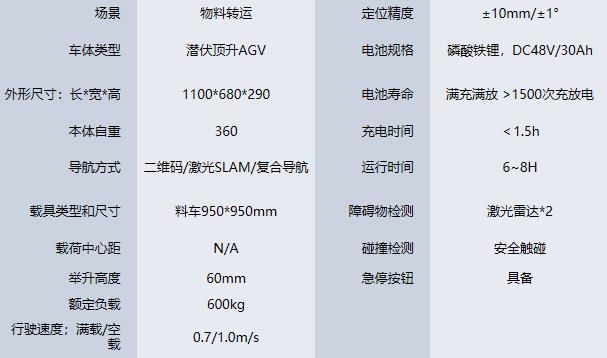

Based on the excellent results and smooth cooperation of the first phase project, the client has once again handed over the task of intelligent upgrading of the second phase electroplating factory to Ant Robotics. By deploying multiple latent lifting AMRs, they can accurately receive and execute tasks such as full load material feeding and empty material truck retrieval issued by the employee PAD, and feedback on the information to the MES system.

Regarding safety: The customer has very high company safety standards to cope with equipment and personnel safety. Based on the understanding of the customer's safety standards from the beginning of the first phase of the project, Ant Robot continues to use high-standard safety design, equipped with dual safety radars and corresponding safety devices, to achieve autonomous safety stopping and 360 ° obstacle avoidance.

With the expansion of customer production line scale and the acceleration of transportation pace, higher requirements have been put forward for the efficiency of the second phase project. Ant Robot's innovative solution introduces a newly upgraded latent lifting AMR, which enables more accurate driving positioning and material docking, cross floor, high flexibility, and multi-scenario linkage. The entire process is quickly deployed and delivered in two months, accelerating the release of production capacity and improving efficiency.

Flexible integration of multiple devices throughout the entire process

In this project, Ant Robot achieved full integration of solutions, connecting with the customer's existing WMS system and multiple types of automation equipment, including automatic doors, elevators, material docking platforms, automated loading and unloading devices, to complete flexible turnover and automated distribution throughout the entire process.

Intelligent algorithm optimization path

Ant robots combine different types of material handling needs and handling processes in different scenarios of the project, introducing the Ant RCS scheduling system, multi-vehicle collaboration, multi-navigation switching, intelligent algorithm optimization path, and efficient multi-path completion of handling tasks, greatly improving work efficiency and supply chain responsiveness.

Ant Robotics has once again created new heights in flexible logistics and lean production with its customers. We look forward to more in-depth cooperation between the two parties in the future, exploring leading innovative solutions and continuously leading the intelligent transformation and upgrading of the 3C industry.