As a flexible logistics guide for indoor and outdoor scenarios, Ant Robot has rich application cases in many industries such as e-commerce, 3C, automotive, pharmaceuticals, machinery, and new energy, and has successfully created multiple benchmark projects. Recently, Ant Robotics has launched another smart logistics transformation and upgrading project in the chemical fibre industry. By introducing Ant's self-developed automated logistics solution that integrates AMR, WMS, and RCS software and hardware, the efficiency of workshop logistics handling is improved, and the entire automation upgrade is achieved.

The customer is a well-known American-funded enterprise that produces high-quality waterproof sealing materials and efficient insulation materials. In the past, manual labour was used for material handling in the factory, resulting in high labour costs and high labour intensity among employees. The flexibility of on-demand warehousing and retrieval was low, and the timeliness of handling was poor, which constrained the development of the enterprise.

The Ant Robot has deployed a flexible logistics solution that combines omnidirectional lifting AMR with multi-equipment linkage WMS and RCS in the factory and production line through an on-site survey of the site. Without the need for workshop renovation, the route is flexibly planned, efficiently completing tasks such as remote distribution of point materials and flexible avoidance of multiple vehicles. It achieves inventory data management, operation management, and intelligent report management, meeting the complex handling needs of multiple lines, warehouses, and tasks.

Full material truck storage: After the production line is offline, manually call AMR to transport the empty material truck to the designated station. After manually loading the material truck, call AMR to transport the full material truck into the warehouse;

Full material truck outbound: manually call AMR to transport the full material truck from a specific supermarket to the designated workstation;

Empty material truck management:

Empty material truck storage: Call AMR to transport the released empty material truck to the designated station;

Empty material truck outbound: Call AMR to transport the empty material truck to the designated station.

Cost reduction and efficiency improvement: Ant AMR collaborates 24 hours a day to connect material distribution between different processes, improve workshop logistics efficiency, and reduce labor costs.

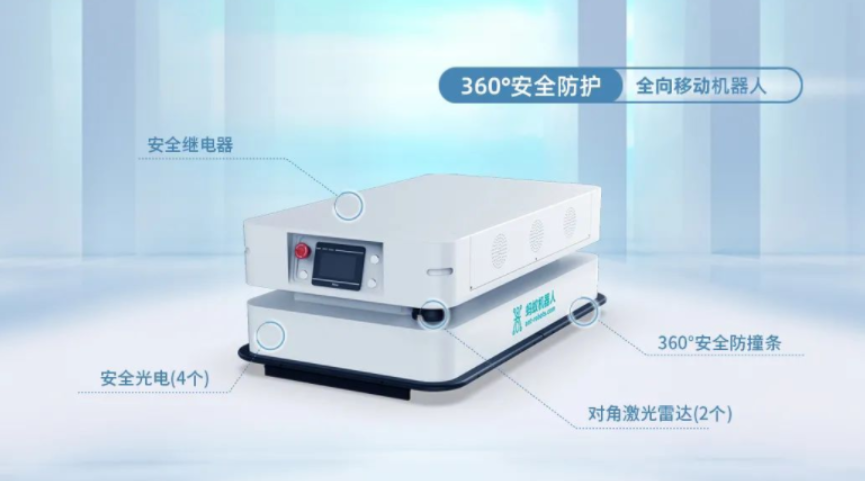

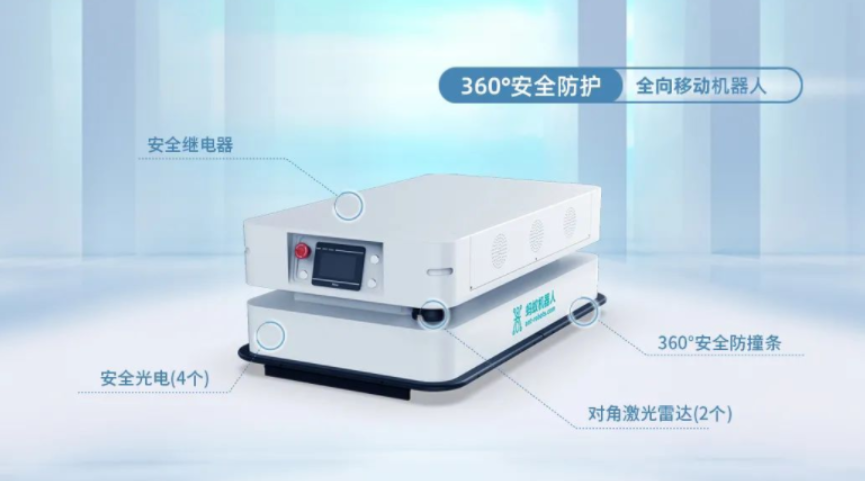

Four-fold safety protection: Adopting a diagonal dual laser design, supplemented by four safety photoelectric devices and safety relays in the front, back, left, and right sides, equipped with safety anti-collision strips around, multiple safety protection, and 360 ° protection to ensure bidirectional safety of personnel and equipment.

Narrow scene application: achieving omnidirectional movements such as forward, backwards, rotation, and lateral movement, solving the difficulty of narrow customer site passages, suitable for narrow material truck handling, narrow passage passage passage, dense storage and other scenarios.

Intelligent interconnection: Through Ant's self-developed WMS system and RCS system, data information and material information are connected, synchronized and automatically updated to achieve automatic transportation of goods in and out of storage and online/offline.

Intelligent charging strategy: Intelligent charging strategies such as idle charging and low battery charging have been developed, and the scheduling system dispatches AMR to actively charge, avoiding situations such as queuing for charging and running out of battery at the same time and improving work efficiency.

Ant omnidirectional lifting AMR adopts the new generation of laser SLAM navigation technology, real-time mapping, and precise positioning of the vehicle's position, ensuring high reliability and stability for continuous operation.

Ant Robotics provides a complete set of intelligent logistics solutions suitable for the chemical fibre industry based on customer and industry needs, covering all scenarios, directions, and coverage. It has successfully implemented multiple industry project cases. With the continuous innovation of Ant Robotics in products, technology, and solutions, as well as its leading project delivery capabilities, it continues to assist more chemical fiber industry enterprises in flexible upgrading.