The customer is a large private technology enterprise that produces high displacement engines and is ranked among the Top 500 Made in China. In the context of the market shifting from increment to stock and intensifying competition, the pace of intelligent transformation has also been accelerated.

Recently, the 5G+engine production line intelligent factory project jointly built by Ant Robotics and leading enterprises in the automotive parts industry has been successfully accepted. We have introduced automated production and logistics systems to our customers while working together. With the advantages of 5G network communication, we have significantly improved production efficiency and created an intelligent factory with efficient human-machine cooperation.

Project difficulties

The task is complex and requires adaptation to multiple product and production lines, covering a process route of more than ten production units;

High requirements for rhythm and system stability;

The scene is complex and requires docking with automatic doors, elevators, and other branded robot systems;

High degree of environmental change and high precision requirements for docking.

Solution

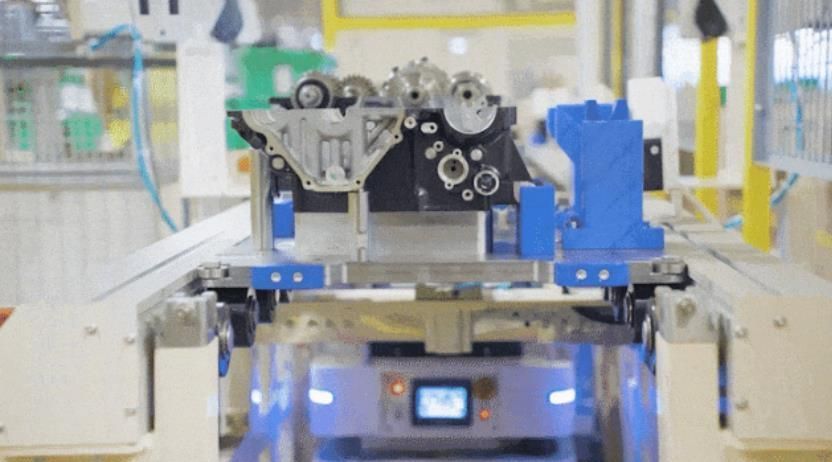

After preliminary communication and on-site operation simulation, Ant Robot has applied a logistics automation solution consisting of 18 omnidirectional lifting AMRs, 10 omnidirectional roller AMRs, Ant RCS scheduling system, and 5G communication module. It realizes the entire production process of the production line from raw materials to semi-finished products to finished products to quality inspection, running through more than ten production units, covering production line docking, line side feeding, empty container return, and other operations. When connecting different production processes to perform assembly operations, it efficiently and accurately docks, continuously and stably operates and helps the efficient operation of factory manufacturing logistics.

The scheme uses omnidirectional lifting AMR and omnidirectional roller AMR, equipped with high-performance industrial grade 5G wireless modules, which can adapt to more complex and demanding industrial scenarios; Integrated laser SLAM positioning and navigation, fast recognition and precise positioning; Configure laser detection sensors and dynamic obstacle avoidance areas to achieve 360 ° safety protection; By using two sets of driving units and four universal wheel drive structures, omnidirectional movements such as forward, backwards, turning, and lateral movement can be achieved; Equipped with remote control function, it is easy to remotely control the robot in abnormal situations.

Ant's self-developed RCS scheduling system links to the upper-level WMS system, achieving automatic updating of material information on the production line. It schedules 28 Ant AMRs to work simultaneously, completing optimal path planning, and real-time status updates, and efficiently completing tasks such as production line docking, material distribution, and reasonable avoidance of multiple vehicles.

Project highlights

5G+AMR

Based on the characteristics of high bandwidth, low latency, and large connection transmission in 5G communication, Ant AMR has faster speed, smoother actions, and higher efficiency. At the same time, the more stable network connection and more efficient data transmission in 5G greatly improve the stability of Ant AMR operation.

Multi-vehicle collaboration and full-process automation

Ant robots, without modifying the customer's on-site environment, import 28 omnidirectional AMRs and combine them with the on-site operation process to achieve efficient collaboration among multiple vehicles. The software scheduling system can collect real-time logistics status information, including work status, task status, operation status, etc., and allocate intelligent tasks to ensure the safe and orderly operation of multiple machines through intelligent transportation strategies.

Intelligent interconnection and digital management

Multiple brands and types of robots gather at the project site, with workers and robots sharing the same channel. The scene is complex, and the Ant RCS scheduling system can interface with robot systems from various manufacturers, and interact with automatic doors and elevators for information technology, intelligent path planning, and vehicle scheduling management. This not only ensures an orderly and clean factory environment but also improves production line and transportation efficiency.

Accurate docking with a high degree of customization

Design intelligent specialized vehicles based on production line handling requirements and scenario applications, accurately connect loading and unloading operations, safely and stably complete assembly tasks, and achieve high-precision material turnover.

Task grading and intelligent scheduling

The Ant Dispatch System implements a priority release strategy, where unloaded robots avoid loaded robots; The robot carrying out assembly tasks passes through the intersection first; Robots travelling at low speeds avoid robots travelling at high speeds, intelligently plan work paths, avoid situations such as locking and traffic congestion, and flexibly respond to complex on-site environments.

Modular design and flexible production

Through modular lean design, traditional processes are transformed into modular units. By combining series and parallel connections, Ant AMR links various modular units to maximize flexible production, suitable for multi-variety and small batch order production. 5G means real-time and higher speed, safer communication, and larger capacity. Ant AMR deeply integrates with 5G communication, co-creating and sharing, fundamentally improving the flexibility of large displacement engine production lines, high-speed production capacity, and work collaboration efficiency, helping customers achieve true cost reduction and efficiency improvement.