Picking is an important part of the warehousing system for warehousing logistics. The speed, flexibility, and accuracy of picking operations often determine the efficiency of order fulfilment and customer service quality, directly affecting the competitiveness of customers in the enterprise.

For the picking scenario, LOGIANT FlyPick intelligent sorting robot and high-speed intelligent sorting system integrate high efficiency, high flexibility, high return, fast delivery, and space-saving advantages. They use AI positioning algorithms to optimize task allocation, efficiently and energy-efficient intelligent sorting, and accelerate the intelligent upgrading of warehouse logistics. At present, we have reached cooperation with leading clients in various industries such as e-commerce and express delivery, achieving project implementation.

High-speed intelligent sorting system

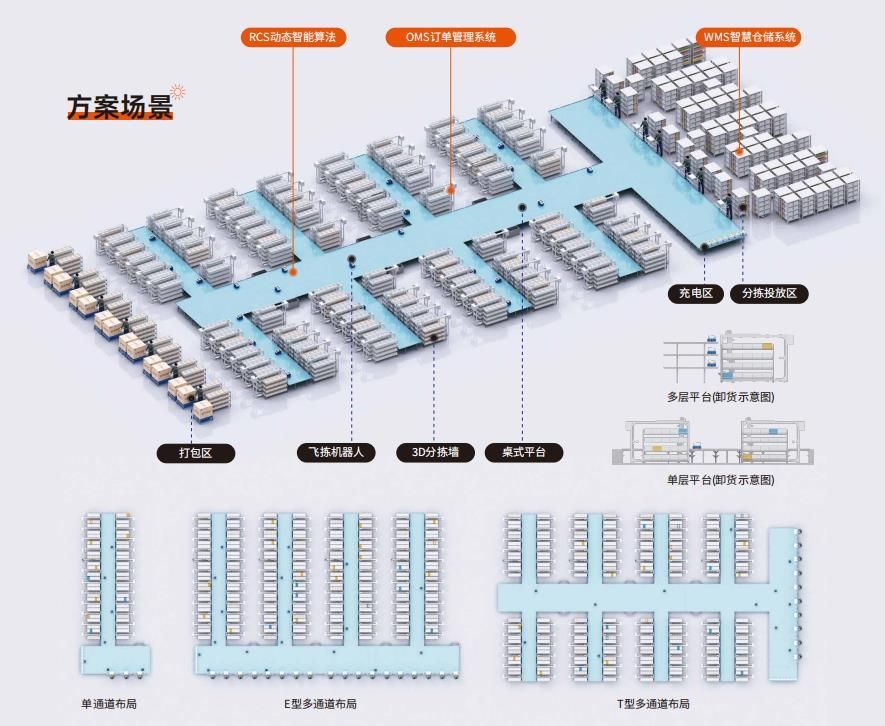

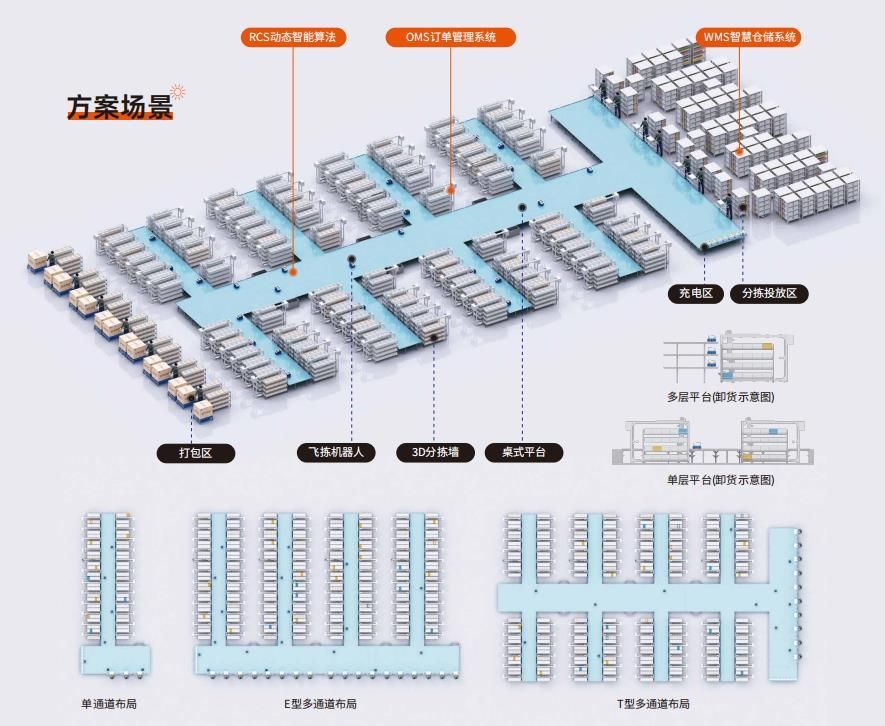

The LOGIANT high-speed intelligent sorting system consists of a FlyPick picking robot, a 3D sorting machine, an intelligent sorting table, and an RCS robot control system. With a small footprint, the system can increase or decrease platform robot tables and adjust the number of sorting slots as needed, with modular design and flexible customization capabilities to meet the needs of different customers.

Mainly suitable for scenarios such as order wave picking, store replenishment (sorted by store), and return processing (sorted and shelved by SKU), it is suitable for the forward and reverse sorting needs of many industries such as express delivery, retail, supermarkets, shoes and clothing.

1. High efficiency

The vehicle can run at a speed of up to 4m/s, working in conjunction with a 3D sorting machine, with a sorting accuracy of up to 99.999%. It has a strong standby, can be charged for 5 minutes, and can run for 4 hours.

2. High flexibility

Highly modular design, customizable layout according to customer needs, increasing or decreasing the number of robots and grids as needed.

3. High return

Compared to traditional sorting, it reduces travel distance, reduces labour load, saves labour costs by up to 80%, has a shorter return period, and an average ROI cycle of fewer than 2 years.

4. Fast delivery

Short production installation and debugging cycle, remote debugging is possible, with a delivery time of up to 2 weeks. The space system in 5 provinces takes up small space and can choose single-layer, double-layer, and multi-layer platforms to achieve maximum utilization of the area.

As one of the largest material handling exhibitions in North America, Ant Robotics, equipped with FlyPick intelligent sorting robots and high-speed intelligent sorting systems, made its debut at the Atlanta Logistics Exhibition MODEX in the United States, showcasing its efficient sorting technology to overseas customers in all aspects and up close. The venue was extremely popular, and visitors flocked to it.

The FlyPick high-speed intelligent sorting system can handle more product sorting in a shorter time and smaller space, with immediate efficiency improvement and cost savings that will directly lead to business growth, helping customers win in the digital age.