In recent years, with the booming development of the e-commerce industry, the demand for timeliness and cost of express logistics has gradually increased. Traditional manual sorting can no longer meet the high standards of production capacity, timeliness, and efficiency. More and more enterprises are turning to intelligent sorting to accelerate the transformation and upgrading of logistics picking.

As a pioneer in smart logistics and intelligent picking, LOGIANT has partnered with China Post to create an intelligent, efficient, and flexible dual-layer desktop sorting system. Within ten days, 80 customized flip-type flying sorting robots were deployed to complete efficient sorting of 5400 items per hour, increasing efficiency by 3-5 times and helping China Post solve sorting problems in one stop.

In logistics sorting scenarios, there are often massive sorting demands for multiple categories, sizes, and packaging specifications. Sorting operations often rely on manual and mechanical work, resulting in low efficiency of manual picking. Especially for some irregular parts, they are not easy to automatically identify and are prone to damage, which increases the difficulty of sorting. At the same time, logistics management is mostly analyzed manually, with high labour costs. Traditional automated equipment is difficult to meet the requirements of transportation efficiency and accuracy.

LOGIANT, in conjunction with the project situation of China Post, has customized the FlyPick robot and a double-layer desktop sorting system, which has a higher capacity to accommodate package shapes and meet the sorting needs of more irregular items, effectively protecting packages from falling off while improving sorting efficiency.

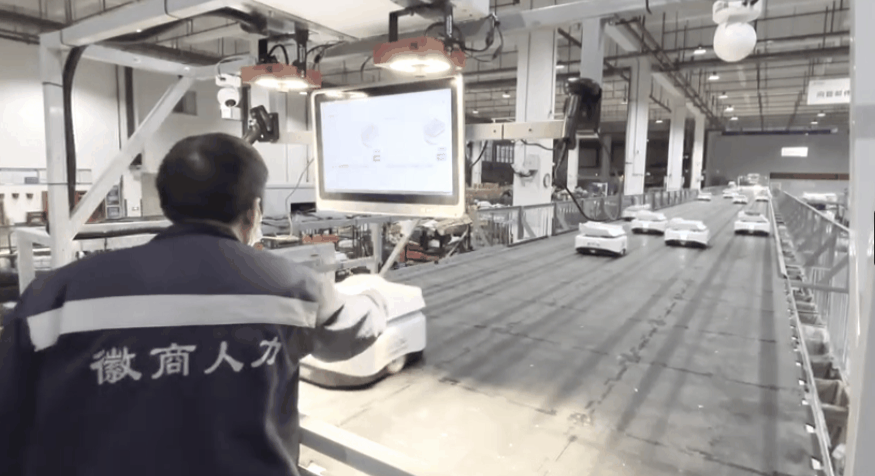

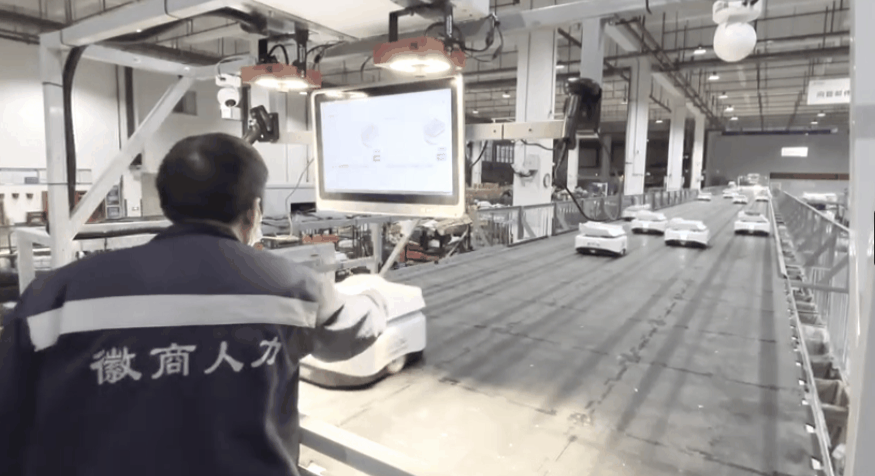

The project covers an area of 300 square meters and has two levels of platforms, with 40 FlyPick robots deployed on each level, totalling 80 flying-picking robots and 130 sorting gates. Operators place logistics packages in the loading port, and the equipment automatically scans package information and matches it with orders to determine the target sorting gate, automatically plans the path, and the flying picking robots quickly place them.

Double leap in human, land, and efficiency

The efficient logistics sorting system of Ant greatly liberates human labour. The work that used to take dozens of people to complete has now been reduced to 4 people, reducing the number of sorting people by more than 50% and increasing sorting efficiency by 4.5 times, resulting in a significant improvement in human efficiency.

Adopting a customized double-layer desktop design, the utilization rate of the venue space is improved within a limited space, and high-precision operations are carried out 24 hours a day, achieving a leapfrog upgrade in intelligent sorting.

Flexible configuration and sorting

Based on the actual operational needs of China Post, optimize the hierarchical layout and flexible configuration to perfectly match different warehousing patterns. It can also support modular design to meet diversified sorting needs as the business grows.

Ten-day deployment for efficient operation

LOGIANT were deployed in China Post's efficient sorting system in just ten days, with 80 flying sorting robots quickly on duty and distributed on a double-layer desktop sorting platform for intelligent operation. The project has been running stably for two weeks after its launch.

Faster deployment also reduces construction costs, minimizes the impact of daily operations, and enables quick investment in a short period. At the same time, the system also has traceability, making logistics management more transparent and flexible, and improving overall management and operation levels.

The successful implementation of the cooperation between LOGIANT and China Post not only achieves a comprehensive upgrade of logistics system informatization, intelligence, and automation but also creates efficient sorting throughout the entire chain with flying picking robots. Its advantages of short delivery, fast speed, and low cost also provide strong momentum for the accelerated development of more picking scenarios.