With the continuous updating and iteration of the warehousing and logistics industry, higher requirements have been put forward for business flexibility and efficiency. How to improve warehousing capacity within limited space? How to create a more flexible picking mode?

Faced with the pain points of digital warehousing development, LOGIANT has launched a "Five in One" Top pick intelligent picking solution with high efficiency, high compatibility, high storage, high flexibility, and high return. It combines high-density storage and efficient goods-to-person picking, subversively reducing operating costs. At the same time, LOGIANT unveiled the Tointelligent picking solution at the SCM FAIR exhibition in Korea, attracting high attention from Korean customers from different industries.

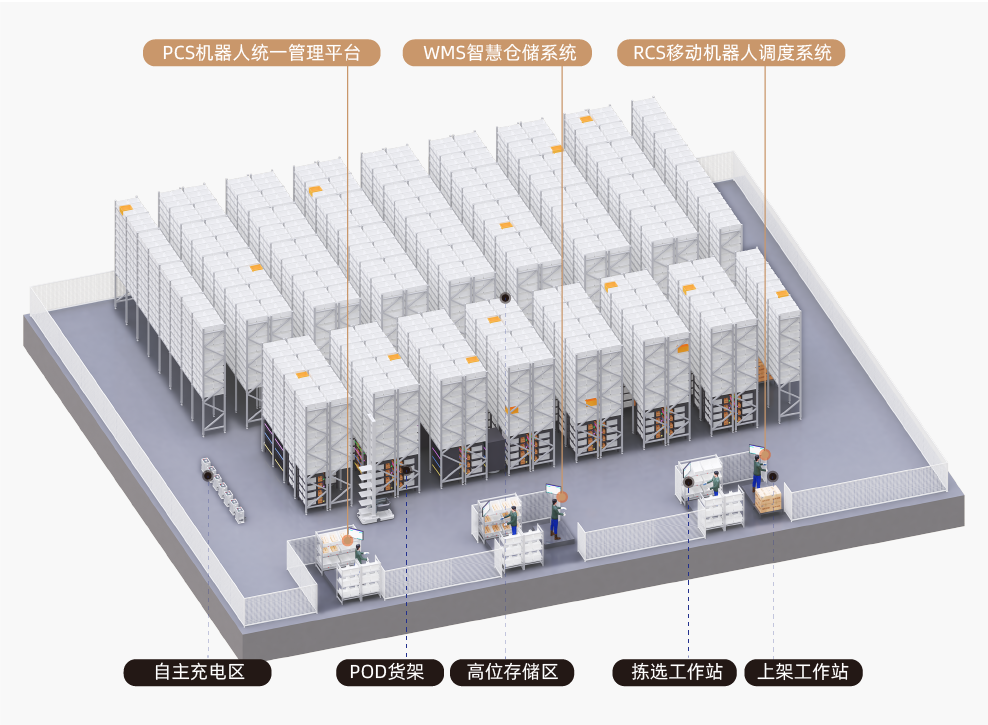

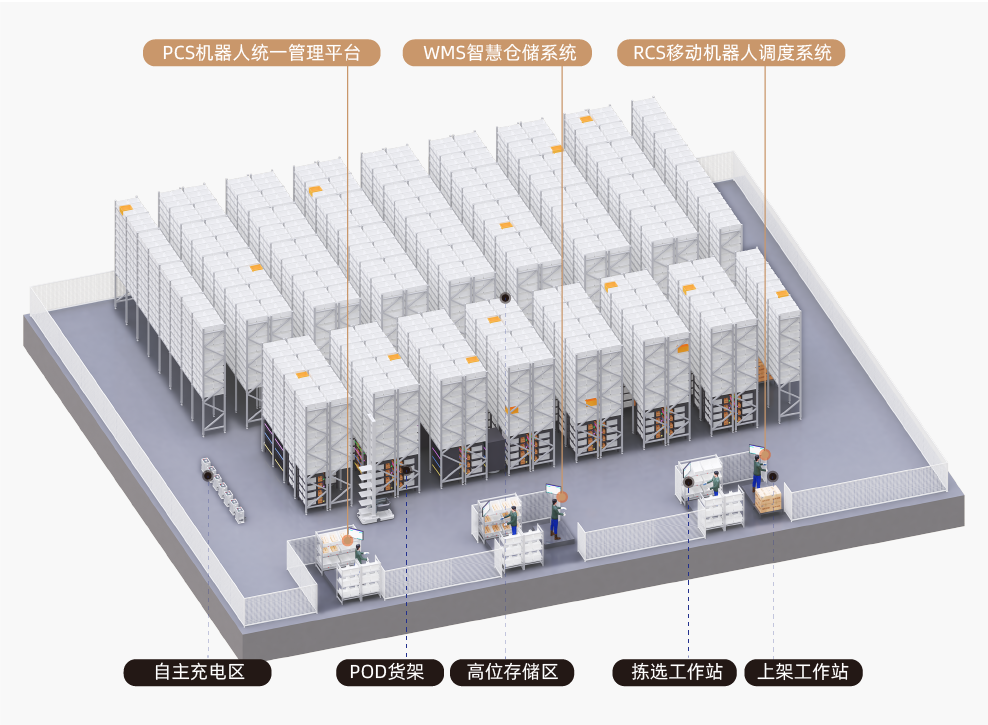

The Ant Robot Top pick up, down, and picking solution is a dual machine collaboration between a bin robot and a latent lifting robot, equipped with an RCS intelligent management platform, a WMS warehouse management platform, and a PCS multifunctional workstation, to achieve the full process automation of loading and unloading, storage, handling, and picking in and out of the warehouse. Pre-sorting during idle hours has created a "black light factory" that reduces costs and increases efficiency. While storing high-density goods, it greatly improves the efficiency of inbound and outbound operations.

A new one-stop intelligent picking mode

Upward storage: Using a material box robot to achieve high-density storage of material boxes/cardboard boxes, fully utilizing the height space of the warehouse.

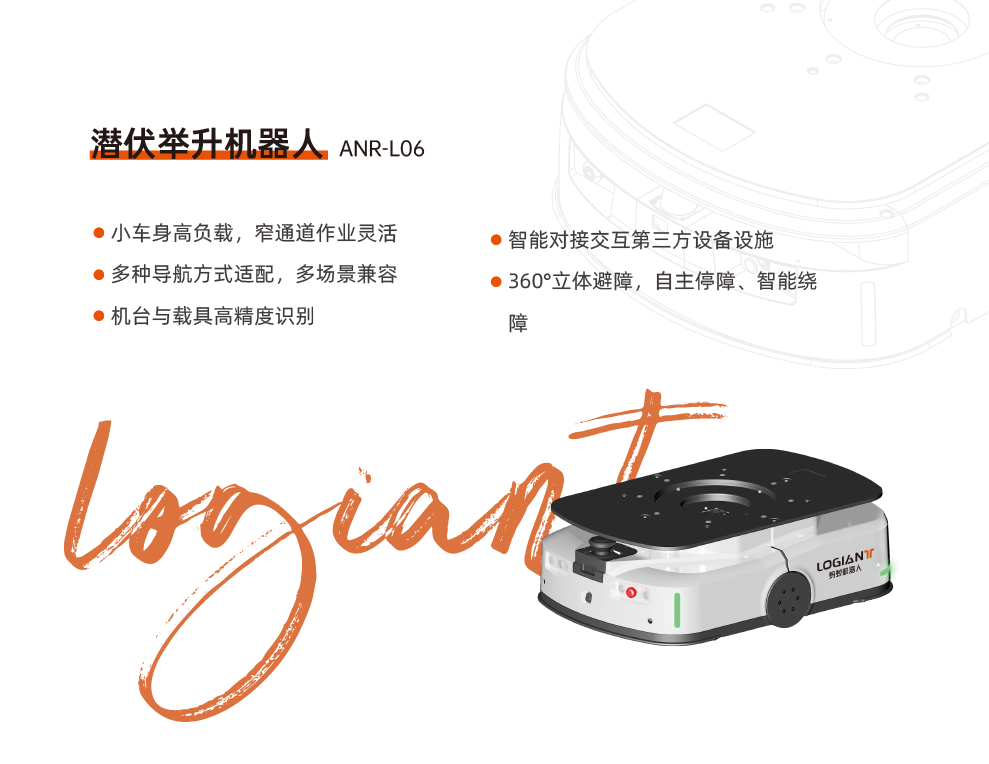

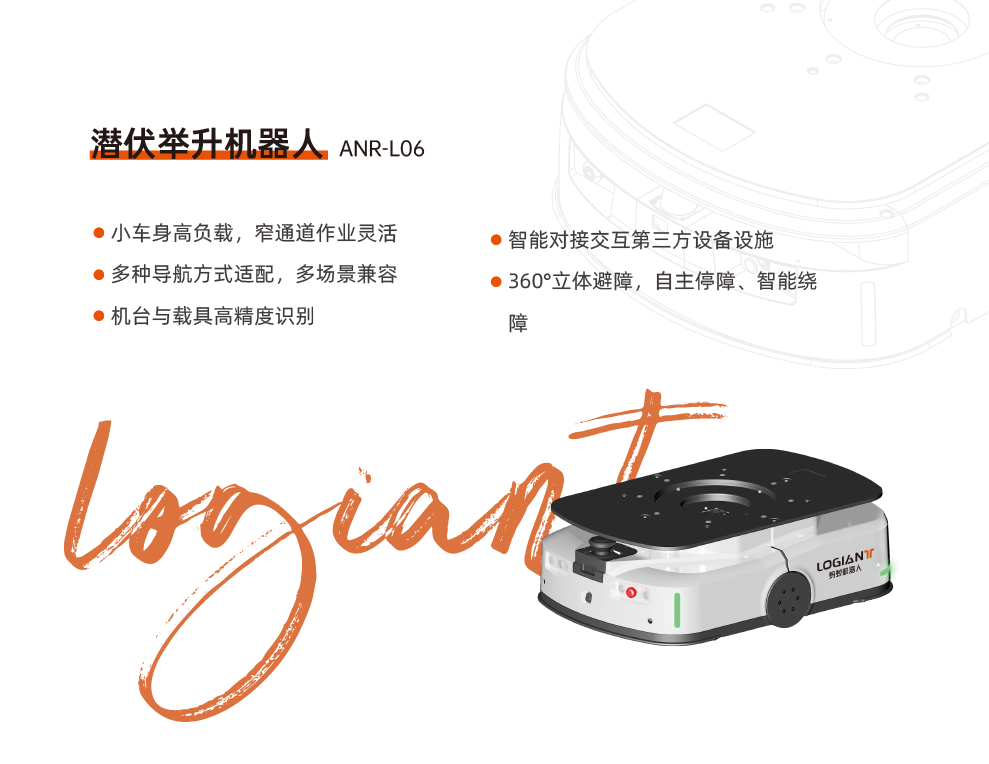

Down picking: Using the form of latent AGV+POD material rack to achieve fast in/out and pre-sorting temporary storage of picked materials, fully leveraging the fast and flexible handling characteristics of latent AGV, and realizing the connection and handling from high-level warehouses to picking positions/in/outstations.

POD material rack: Multiple types can be set, such as material box POD, layer board POD, bottom tray, etc., customized design according to application scenarios.

Optimization of the picking process, pre-sorting during idle hours, balancing peak and valley flow

Support full box picking and split picking, with one-stop storage/inbound/outbound of goods

Up storage and down picking, high space utilization, covering 0.5-10 meters of three-dimensional storage space

The bottom layout of the shelves is flexible, suitable for different carriers such as ingredient boxes/pallets, and can integrate multiple intelligent terminals

High hit rate, low investment cost, greatly reducing investment return cycle

52% increase in storage capacity, fully utilizing warehouse height.10% reduction in construction costs, pre-sorting for outbound shipments, improving shelf hit rate, and saving AGV quantity.Improve homework efficiency by 50%, reduce manpower demand by 33%, increase shelf hit rate, reduce AGV switching times, and eliminate the need for personnel to climb high, thereby improving homework efficiency.Operation and maintenance costs:50% reduction in operation and maintenance costs, reduced number of equipment, and reduced power consumption.

■ Split picking, full box picking, large/medium/small piece picking, and irregular piece picking

■ Picking in various business scenarios such as To B and To C

■ Picking explosive and fast-moving consumer goods

SCM FAIR 2023 in South Korea

On September 6th, SCM FAIR2023 in South Korea grandly opened at the International Exhibition Center in Gaoyang City. As one of the leading supply chain management expos in South Korea, LOGIANT launched a disruptive TopPick intelligent picking solution in the Korean market. They interacted with exhibition guests, demonstrated on-site, and intuitively demonstrated the strength of the product and the innovation of the solution.

LOGIANT always focuses on the pain points and needs of customers, continuously conducts research and innovation, and empowers logistics and warehousing with leading products and solutions to achieve higher value. The TopPick intelligent picking solution maximizes the utilization of warehouse space, responds to market demand with high flexibility, efficiently reduces customer costs, and promotes intelligent upgrading of warehousing.